+8617766397620

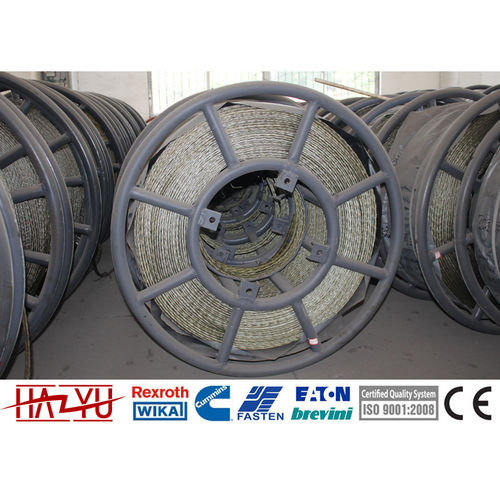

+8617766397620High Strength Steel Braided Rope Pulling Ropes Heavy Duty

Product Details:

- Material High Strength Steel

- Style Braided

- Rope Width Varies (typically 8mm to 28mm)

- Product Type TYFUX Anti-Twisting Steel Braided Rope

- Rope Strength Heavy Duty - Designed for High Tensile Loads

- Rolls in a Packet As per order requirement

High Strength Steel Braided Rope Pulling Ropes Heavy Duty Price And Quantity

- 1000 Meter

- Galvanized/Anti-Rust Coated

- Custom Lengths as per Requirement

- Anti-Twisting Design

- Heavy Lifting, Electrical Cable Pulling, Construction, Industrial Applications

- High

- Steel Grey

- Superior flexibility for ease of use

- As per order

- Depends on Rope Diameter, typically ranges from 5 tons up to 80 tons

High Strength Steel Braided Rope Pulling Ropes Heavy Duty Product Specifications

- Braided

- Heavy Duty - Designed for High Tensile Loads

- Varies (typically 8mm to 28mm)

- As per order requirement

- TYFUX Anti-Twisting Steel Braided Rope

- High Strength Steel

- Galvanized/Anti-Rust Coated

- Custom Lengths as per Requirement

- Anti-Twisting Design

- Heavy Lifting, Electrical Cable Pulling, Construction, Industrial Applications

- High

- Steel Grey

- Superior flexibility for ease of use

- As per order

- Depends on Rope Diameter, typically ranges from 5 tons up to 80 tons

High Strength Steel Braided Rope Pulling Ropes Heavy Duty Trade Information

- Shanghai,Tianjin,Ningbo

- Telegraphic Transfer (T/T), Letter of Credit (L/C)

- 10000 Meter Per Month

- 35 Days

- container

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- All India

- iso9001

Product Description

TYFUX Anti-Twisting Steel Braided Rope

Anti-twisting braided wire rope with high strength hot dip galvanized steel quality air processed by the special process of special woven rope line. It has high strength, good flexibility, corrosion rust-proof, not to fight the golden hook, and difficult to tie, long life and so on. Tension applied to pay-off power lines construction, lifting equipment with the balance shaft and the tail rope of mine, port and other major lift crane wire rope does not rotate when the required place.

|

Technical specification |

|||||||

|

Item no. |

Normal Diameter(mm) |

Structure |

Breakage tension(kN) |

Standard Length(m) |

Diameter of spool(mm) |

Total weight(kgs) |

Empty spool weight(kgs) |

|

YL9-12x19W |

9 |

12 Strands |

55 |

1000 |

850 |

294 |

32 |

|

YL10-12x19W |

10 |

12 Strands |

67 |

1000 |

1000 |

390 |

47 |

|

YL11-12x19W |

11 |

12 Strands |

80 |

1000 |

1000 |

454 |

47 |

|

YL12-12x19W |

12 |

12 Strands |

100 |

1000 |

1100 |

552 |

52 |

|

YL13-12x19W |

13 |

12 Strands |

120 |

1000 |

1100 |

642 |

52 |

|

YL16-12x19W |

16 |

12 Strands |

158 |

1000 |

1250 |

886 |

60 |

|

YL18-12x19W |

18 |

12 Strands |

210 |

1000 |

1400 |

1154 |

74 |

|

YL20-12x29Fi |

20 |

12 Strands |

250 |

1000 |

1400 |

1394 |

74 |

|

YL22-12X29Fi |

22 |

12 Strands |

320 |

1000 |

1400 |

1258 |

74 |

|

YL24-12x29Fi |

24 |

12 Strands |

360 |

800 |

1440 |

1474 |

78 |

|

YL26-12x29Fi |

26 |

12 Strands |

420 |

700 |

1440 |

1723 |

78 |

|

YL28-12x29Fi |

28 |

12 Strands |

480 |

500 |

1600 |

1401 |

116 |

|

YL30-12x29Fi |

30 |

12 Strands |

540 |

500 |

1600 |

1666 |

116 |

|

YL20-18x19W |

20 |

18 Strands |

300 |

1000 |

1440 |

1368 |

78 |

|

YL22-18X29Fi |

22 |

18 Strands |

389 |

800 |

1440 |

/ |

78 |

|

YL24-18x29Fi |

24 |

18 Strands |

440 |

800 |

1440 |

/ |

78 |

|

YL28-18x29Fi |

28 |

18 Strands |

580 |

500 |

1600 |

1655 |

116 |

|

YL30-18x29Fi |

30 |

18 Strands |

658 |

500 |

1600 |

1900 |

116 |

Engineered for Maximum Strength and Durability

Our steel braided ropes are manufactured with high-strength steel fibers woven into a durable braided pattern. The anti-twisting design maintains rope integrity under heavy loads and reduces operational risks. With a heavy-duty construction that withstands high tensile stresses, our ropes perform reliably in even the toughest industrial and construction applications.

Advanced Corrosion Protection and Flexibility

Featuring a galvanized and anti-rust coated surface, these ropes display remarkable resistance to environmental degradation. Their steel grey color and innovative coating provide long-lasting performance while the superior flexibility ensures they are easy to handle, install, and maneuvereven in restricted spaces or complex setups.

Custom Specifications & Wide Applications

Available in a variety of widths and custom lengths as per project specifications, our ropes are suitable for cable pulling, heavy lifting, and general industrial use. Orders can be tailored to meet unique requirements and are dispatched in rolls according to your preferred packaging quantities.

FAQs of High Strength Steel Braided Rope Pulling Ropes Heavy Duty:

Q: How do I select the appropriate rope diameter and breaking load for my application?

A: The ideal rope diameter and breaking load depend on the weight and nature of your lifting or cable pulling task. Typically, ropes are available in diameters from 8mm to 28mm, with breaking load capacities ranging from 5 tons to 80 tons. Consult with our technical team or refer to your applications load requirements to determine the best option.Q: What surface treatments are applied to these steel braided ropes and how do they benefit the product?

A: These ropes are treated with a galvanized and anti-rust coating, enhancing corrosion resistance and extending product lifespan, even in outdoor or harsh environments. This ensures reliable performance regardless of exposure to moisture or chemicals.Q: When and where should these heavy-duty steel braided ropes be used?

A: These ropes are well suited for heavy lifting, electrical cable pulling, and a variety of industrial and construction applications, especially where high tensile strength and corrosion resistance are crucial. They are ideal for use in both indoor and outdoor environments.Q: What is the process for ordering custom lengths or diameters?

A: Simply specify your required rope length and diameter when placing your order. As a manufacturer and distributor, we accommodate custom requests and MOQ is based on your order specifications. Our team will guide you through the selection and ordering process.Q: How does the anti-twisting design improve rope performance during usage?

A: The anti-twisting design minimizes rotational movement and prevents rope tangling during operation. This enhances safety, preserves rope integrity, and ensures dependable handling, especially under dynamic or high-tension conditions.Q: Could you explain the flexibility of this steel rope and its benefits?

A: Our steel ropes are constructed to provide superior flexibility, allowing them to be easily installed, maneuvered, and used in complex setups. This feature reduces manual effort and facilitates smooth, efficient workflows, particularly in demanding industrial tasks.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Anti-Twisting Steel Braided Rope' category

|

WUXI HANYU POWER EQUIPMENT CO., LTD

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

+86 17712397510

+86 17712397510 Send Inquiry

Send Inquiry